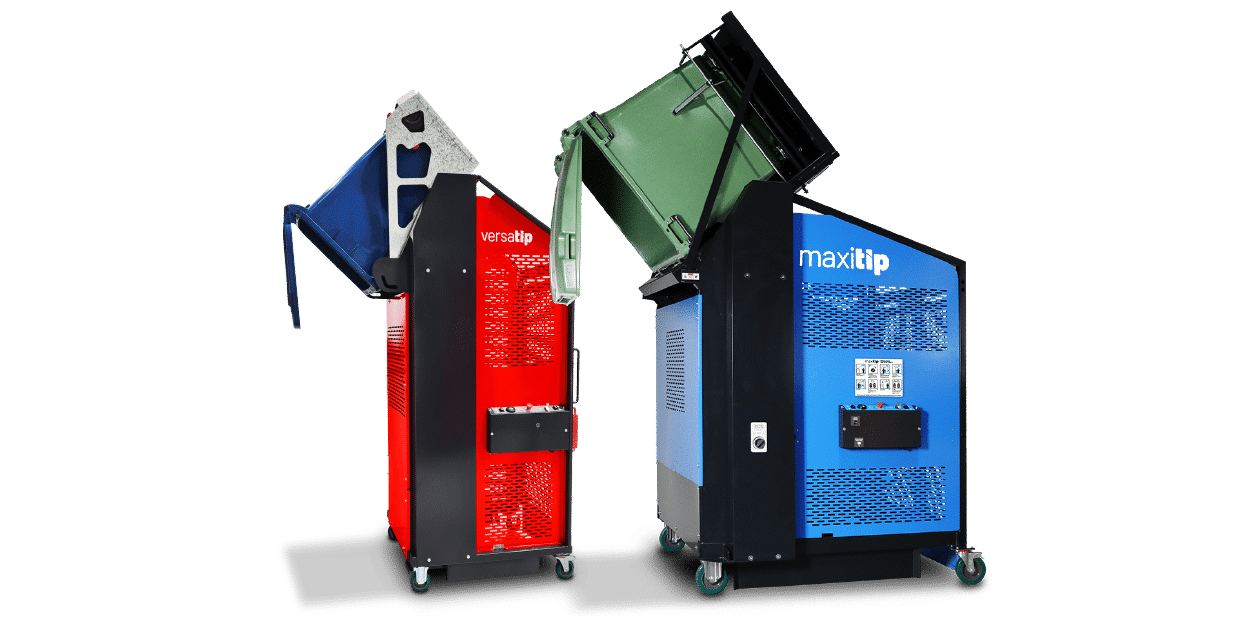

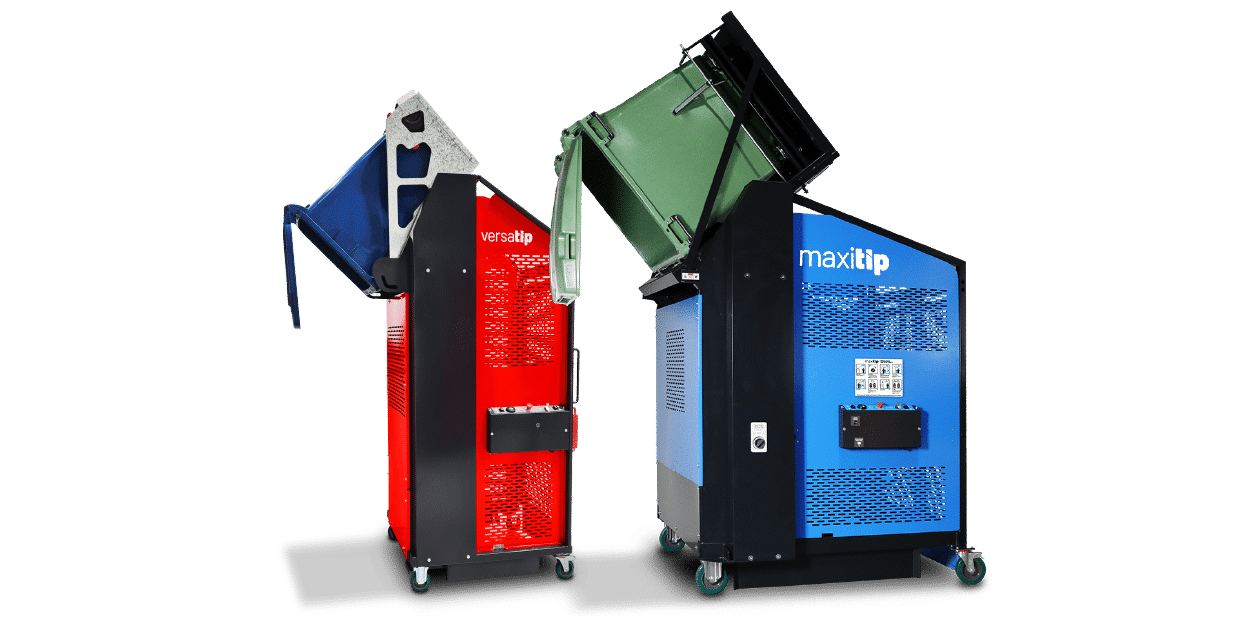

Versatip Bin Tipper - 1200mm Tip

- Specifications

- Suit Bins 80-240 litres

- 1200mm Tip Height

- Battery, Solar, 1 & 3 Phase Options

Engineered for Safety & Efficiency in Waste Management. From reducing manual handling injuries to boosting operational Efficiency, our Wheelie Bin Tippers are designed for demanding waste & recycling environments.

Manufactured with high-quality materials and premium finishes, our wheelie bin tippers are built to withstand the demands of daily use, providing long lasting durability you can count on.

The Veratip wheelie bin lifter range is ergonomically designed to reduce strain on the operator and remove the risks traditionally associated with emptying wheelie bins.

Operator safety was of paramount importance in the design of the Versatip. Class-leading safety features have been included to ensure the safety of the operator.

We offer tailored solutions to meet your business’s needs, whether it’s bin compatibility, load capacity, or specialised settings. Get in touch with your unique specifications and we’ll create the perfect solution for you.

We have owned a Versatip bin lifter from Sitecraft for the past few years. It is a strong durable machine and still looks as good as the day it arrived. Ours has the optional solar charging, so we have never had to plug it in to charge. This machine is hand over fist better than any other bin lifter we have owned.

The responsiveness from the sales staff and the techs has just been outstanding. I would highly recommend your company to anybody who is looking for lifting equipment. The level of support and service is fantastic

Sitecraft is a leading provider of material handling solutions in Australia, dedicated to delivering innovation, quality, efficiency and sustainability.

Our commitment to supplying fit for purpose equipment brings a strong customer focused culture to the organisation. We tailor our products to meet our customer’s specific needs, fostering long-term relationships based on integrity and satisfaction.

With over 25 years of industry experience, Sitecraft have provided products and services to a wide range of industry sectors and environments in Australia, including; manufacturing, logistics, mining, defence and government organisations.

A wheelie bin tipper is a fit for purpose piece of equipment that makes difficult task easy. Wheelie bin tippers lift and then tip, allowing the operator to empty the contents of a wheelie bin simply, easily, and safely into a lager bin, process line or sorting equipment.

A wheelie bin tipper is a specialized piece of powered equipment designed to simplify the often difficult and manual labor-intensive task of emptying wheelie bins. This tool lifts and tips the bin, allowing its contents to be safely and easily emptied into a larger bin, processing line, or sorting system. By reducing the physical strain on operators and improving efficiency, wheelie bin tippers are ideal for industries that handle waste, recycling, or bulk materials regularly. They’re built to make the job faster, safer, and more convenient.

Bin tippers are available in different models, from manual hand winch style utilising a cable lifting action to electric over hydraulic which uses chains and hydraulic ram to lift a dedicated cradle through a engineered lifting and tipping action.

Wheelie bin tippers operate by lifting and tipping wheelie bins using a specially designed cradle. Depending on the model, they work in different ways:

Manual Hand Winch Models: These use a cable lifting mechanism. The operator manually turns a winch, which raises the cradle and tips the bin. These are simple and cost-effective, ideal for lighter and less frequent workloads.

Electric Over Hydraulic Models: These use a combination of hydraulic rams and chains to lift and tip the cradle. With just the press of a button, the system performs the heavy lifting for you, making it ideal for larger or more frequent loads.

To use a wheelie bin tipper:

Versatip bin tippers as designed to work with regular 2 wheeled bin sizes including 80lt, 100lt, 120lt and 240lt. The Versatip360 will accommodate for these sizes plus also the larger 360lt bins. There is a specialised version which is dedicated to the ‘Brute Bins’ and ‘Thor Bins’ which are found in many processing facilities.

Versatip Wheelie Bin Tippers are designed to handle a wide range of bin sizes, ensuring flexibility for various needs.

Always confirm compatibility with your specific bin type when selecting a Versatip model to ensure optimal performance and efficiency.

The Versatip Bin Tippers come standard as mobile units fitted with four European wheels for manoeuvrability. The bin face has two fixed direction wheels, and the operator end has 2 braked swivel castors. The4se bin tippers can be operated as standalone, no floor fix down required and neither do they need to be clipped or connected to whatever they are tipping in to. Bearing all this in mind, there is no installation required provided the required power source is readily available.

No, installation is not required for Versatip Wheelie Bin Tippers. These units are designed as fully mobile systems with four European wheels for easy maneuverability. The bin-facing end has two fixed-direction wheels for stability, while the operator end features two braked swivel castors for controlled movement.

Versatip tippers operate as standalone units, meaning they don’t need to be bolted down to the floor or clipped to the equipment or containers they are tipping into. Simply ensure that a compatible power source is readily available, and your Versatip is ready to use right away. This makes them highly versatile and easy to integrate into your workflow.

As we all relate to, anything that is mechanical requires some varying degree of maintenance. Longevity has been at the forefront of all design decisions when the Versatip was created, special wear resistant rollers have been incorporated along with other high-quality componentry to provide peace of mind. Recommended service intervals will vary according to usage and the surrounding environment. Typically, the recommendation would be for servicing 12 monthly and bi-monthly for very demanding applications.

Like any mechanical equipment, the Versatip Wheelie Bin Tipper requires regular maintenance to ensure optimal performance and longevity. Built with durability in mind, it features wear-resistant rollers and high-quality components designed to reduce the need for frequent repairs.

Maintenance Guidelines:

Adhering to these guidelines will keep your Versatip running smoothly and extend its service life. Always refer to the Sitecraft Product Manual and maintenance schedule for your specific model.